Soft dB's comprehensive blast monitoring solutions combine state-of-the-art instrumentation with expert technical support and automated reporting. Our turnkey approach ensures reliable, actionable data, helping you optimize mining and construction activities while minimizing risk. This enables project managers to make informed decisions that enhance safety, ensure regulatory compliance, and maintain positive community relations.

What Is Blast Monitoring & Why It Matters

Definition & Key Objectives

Blasting operations, while essential to many industrial activities, can pose significant risks if not carefully managed. Excessive ground vibration and air overpressure can lead to structural damage, regulatory violations, operational downtime, complaints from nearby communities and sometimes lawsuits. To mitigate these risks, precise monitoring and accurate data reporting are essential.

Blast monitoring involves measuring vibrations and acoustic shock waves generated during blasting operations, whether in the mining industry or other industrial sectors. It focuses on key factors such as ground vibration levels and air overpressure to assess their potential impact on surrounding structures. These measurements are essential to determine whether blasting activities remain within safe and acceptable limits.

Blast monitoring matters because there are strict regulations that must be respected. Exceeding these limits can result in structural damage, community complaints, and costly fines. Monitoring helps ensure compliance with environmental and safety regulations, protects nearby infrastructure, and demonstrates a company's commitment to responsible operations. It also supports better community relations by reducing the risk of disturbances.

When, Why and Where Is It Used?

Blast monitoring is primarily used when blasting operations take place near sensitive buildings or in urban areas.

It offers numerous advantages. Most notably, it reduces downtime, legal liability, and environmental impact. It also helps ensure compliance with industry standards, while enhancing the productivity and efficiency of operations.

While blast monitoring is most commonly used in the mining industry and quarries, it is also widely applied on construction sites, in tunnelling, demolition work, and even in military operations. It's important to note that different environments and use cases may require tailored monitoring systems.

For instance, in the mining sector, vibration monitoring is primarily focused on safety, operational efficiency, and fragmentation quality. In contrast, for urban blasting, such as in construction or demolition, monitoring is essential for limiting the impact on surrounding communities and maintaining compliance with regulations.

How Blast Monitoring Works: Systems, Sensors & Processes

Core Components of a Vibration Monitoring System

A vibration monitoring system consists of a seismograph, which may include a geophone, MEMS sensor, or accelerometer, connected to an acquisition system that transmits the measured data to a central monitoring station. The station then uploads blasting event data to the cloud, making it accessible remotely in real time. Operators can receive automatic notifications with blasting details via text message or email, eliminating the need for additional equipment or on-site personnel to manage the stations.

Key Metrics Measured

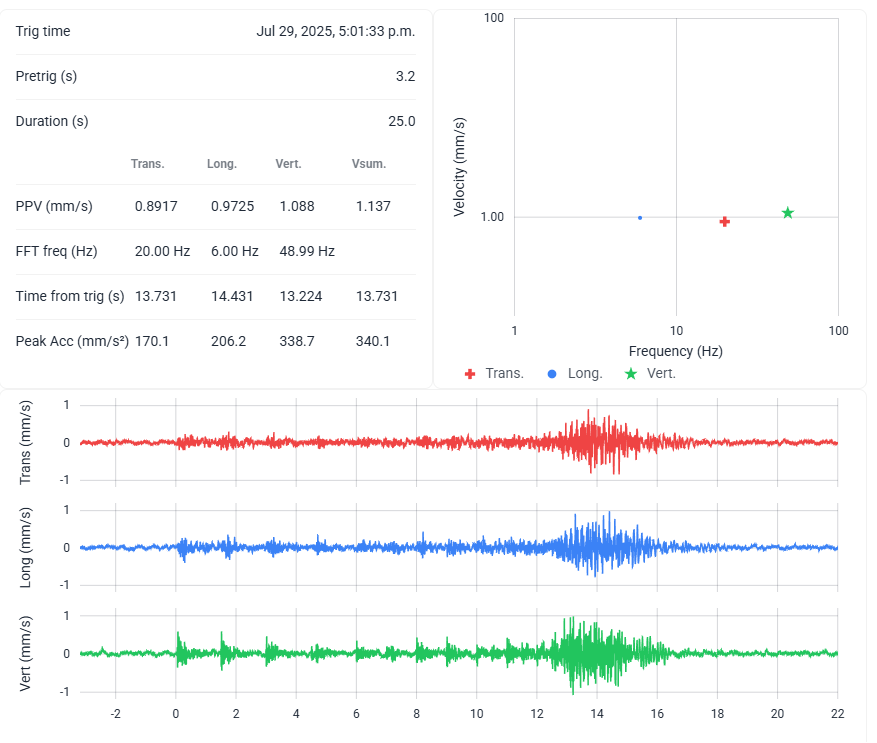

A vibration monitoring system can take a variety of measurements. These measurements include Peak Particle Velocity (PPV) and Peak Vector Sum (PVS), overpressure as well as peak vibration frequency and sometimes displacement.

Data Collection and Analysis Workflow

The monitoring stations provide real-time 24/7 surveillance. They automatically transmit data when a blast occurs, eliminating the need for any pre-blast setup. The stations continuously collect data and send notifications in the event of a blasting operation, followed by a post-blast analysis. This way, you're instantly notified following a blast.

Industry Standards & Compliance: What You Need to Know

Global Standards and Regulations

Different vibration standards are in place around the world. For example, to name only a few, in the United States, the OSMRE oversees vibration regulations, and the applicable standard is the USBM RI 8507. In Europe, DIN 4150-3 is used, while in Australia, the relevant standard is AS 2187.2. In Canada, regulations tend to be more flexible. In Quebec, for instance, blast events from the mining sector are governed by Directive-019.

The main differences between these standards lie in the allowable limits, which are often based on the frequency of the vibration event. With so many different standards in effect, blast monitoring becomes essential to ensure compliance, avoid delays, and prevent fines.

It is advisable to always meet the most stringent applicable standard.

Avoiding Fines, Delays & Lawsuits

The primary objective in blast monitoring is to prevent damage and cracking in sensitive structures located near blasting operations. As such, monitoring stations play a critical role in documenting compliance and providing reassurance to the surrounding community. A reliable monitoring solution not only helps you stay compliant with regulations, but also minimizes the risk of project delays and potential legal action.

Choosing the Right Blast Monitoring Solution

Key Buying Criteria

Choosing the right blast monitoring solution is not easy, as many key features must be considered.

Our system is designed with precision and fully complies with the ISEE Performance Specification for Blasting Seismographs and multiple other regulations. It offers a measurement range that adapts to different vibration levels, typically up to 50 mm/s, and is built to last, with an IP68 durability rating that meets all industry standards. Sensors, such as the Smart Geophone Sensor, also allows to measure key metrics used for sensitive laboratory instruments.

Our software and data visualization tools are developed entirely in-house, allowing us to ensure both reliability and ease of use. One critical factor that should never be overlooked is local support and access to reliable data, something we are proud to deliver with excellence.

Additionally, lab calibrations are only required once a year, so you don't lose valuable time on frequent maintenance.

Types of Systems Available

Real-time networked monitoring systems offer several advantages over traditional portable monitors. While both methods have their place depending on the project, real-time systems provide a more efficient and scalable solution for modern blasting operations. Our real-time solution is specifically designed to optimize blasting operations by making data comparison between blasts simple and accessible.

| Portable Monitors | Real-Time Networked System | |

|---|---|---|

| Monitoring system | Standalone monitors | Networked system |

| Data Availability | Post-event data | Real-time data |

| Operation & Analysis | Manual | Automated |

| Automatic Data Sharing | No | Yes |

| Access to Vibration Expertise | No | Yes |

In-House Monitoring vs. Outsourcing

When it comes to blast monitoring, companies often face the choice between managing everything in-house or hiring specialized experts. Doing it yourself can be cheaper and flexible, but it requires time, technical know-how, and proper maintenance of equipment. On the other hand, hiring specialists ensures accuracy and compliance but can sometimes be expensive, especially for smaller operations.

To address this gap, we offer Blast Monitoring as a Service (BMaaS), a practical solution where companies can rent monitoring stations for one-time use without committing to a full investment.

The key advantage is that while clients can handle most of the process themselves, tasks like installation, maintenance, and instrumentation management require a certain level of expertise, which we are willing to provide.

Having a direct line to the manufacturer for support is a crucial part of our approach and one of our greatest strengths.

Monitor Your Environmental Impact

Vibration monitoring helps ensure that safety and regulatory limits are respected, minimizing the risk of environmental damage.

When it comes to the protection of the environment, hydrophones are used to measure underwater noise or pressure levels in lakes, which is particularly important for protecting wildlife, a requirement often mandated by Fisheries and Oceans Canada during blasting operations.

Understanding the impact of industrial activity on both humans and animals is essential to protect them. A monitoring system capable of measuring multiple types of environmental contaminants such as vibrations, overpressure and underwater noise allows us not only to meet current regulatory requirements, but also to adapt to future challenges as standards evolve.

From Monitoring to Mastery: Streamline Your Blast Monitoring Setup

Precision is crucial in blast monitoring, which is why we offer a tailor-made solution that allows you to synchronize all your monitoring stations, ensuring no vibration event is missed and reducing the likelihood of false positives.

Introducing Soft dB's Master Trigger: a next-level, patented system that enhances the accuracy and efficiency of event detection.

Master Trigger enables multiple monitoring devices, including vibration, overpressure, and noise sensors, to record simultaneously. It intelligently filters out false triggers, ensuring that only meaningful data is captured. It also supports various trigger types, such as acoustic, geophysical, or electrical, making it adaptable to a wide range of environments.

Master Trigger is the ideal solution for complex or multi-location blasting operations where precise coordination is essential.

After each event, you'll receive an automatic summary report by email or text message after any blast event, no need for a worker to manually gather and analyze the data. With our state-of-the-art solution, you can achieve both efficiency and cost-effectiveness.

Blast Monitoring FAQ

What are typical safe vibration limits for different types of structures?

Typical safe vibration limits for structures can vary from one project to another, depending on factors such as the type of structure, its condition, and its intended use. Generally, these limits are expressed in terms of Peak Particle Velocity (PPV) and for sensitive lab instruments in RMS velocities.

Industry standards commonly used to define safe vibration thresholds include DIN 4150 (widely used in Europe for evaluating building vibrations) and USBM RI 8507 (used primarily in North America for blasting near structures).

It is important to distinguish between compliance limits and human perception thresholds, which are much lower. Even when vibrations are within safe regulatory limits, they may still be felt by occupants and raise concerns.

How far should I place sensors from the blast site for accurate readings?

It's not the distance from the blast site that matters most, but the distance between the sensitive receiver and the sensor. In general, the sensor should be placed between the vibration source and the sensitive structure to properly measure the impact, closer to the sensitive structure.

Should I use geophones or accelerometers for my project?

Geophones are generally the way to go, except for underground mines where strong motion due to human activities can happen. In that case, accelerometers or MEMS can be a suitable replacement to prevent saturation from low frequency strong motions during seismic events.

What standards and regulatory thresholds govern blast monitoring?

Blast monitoring sensors comply with the ISEE Performance Specification for Blasting Seismographs. However, different vibration standards are in place around the world.

For example, to name only a few, in the United States, the OSMRE oversees vibration regulations, and the applicable standard is the USBM RI 8507. In Europe, DIN 4150-3 is used, while in Australia, the relevant standard is AS 2187.2. In Canada, regulations tend to be more flexible. In Quebec, for instance, blast events from the mining sector are governed by Directive-019.

The main differences between these standards lie in the allowable limits, which are often based on the frequency of the vibration event.

How frequently does monitoring equipment require calibration?

It depends on the applicable standard. In North America, for example, the requirement is generally annual, as per ISEE guidelines. That said, it ultimately comes down to the specific regulations in place. Regardless of the required inspection frequency, modern sensors now include built-in self-check features that continuously verify proper functionality, a capability that has become essential in today's monitoring systems.

How can I minimize false triggers?

Use of the patented Master Trigger system, developed by Soft dB, will only send reports and alerts when events are not classified as false positives.

What are the pros and cons of real-time networked systems vs. portable monitors?

Real-time networked monitoring systems offer several advantages over traditional portable monitors. While both methods have their place depending on the project, real-time systems provide a more efficient and scalable solution for modern blasting operations. Our real-time solution is specifically designed to optimize blasting operations by making data comparison between blasts simple and accessible.

| Portable Monitors | Real-Time Networked System | |

|---|---|---|

| Monitoring system | Standalone monitors | Networked system |

| Data Availability | Post-event data | Real-time data |

| Operation & Analysis | Manual | Automated |

| Automatic Data Sharing | No | Yes |

| Access to Vibration Expertise | No | Yes |

What is the correct orientation and installation method for vibration sensors?

In general, either pointing towards the direction of the blast or to the north, depending on the standard and also if permanent stations are installed. In general, adequate coupling with ground is required, such as burying the sensor or firm attachment to the structure or the ground.

Are there affordable options or service models for smaller operators?

When it comes to blast monitoring, companies often face the choice between managing everything in-house or hiring specialized experts. Doing it yourself can be cheaper and flexible, but it requires time, technical skills, and proper maintenance of equipment. On the other hand, hiring specialists ensures accuracy and compliance but can sometimes be expensive, especially for smaller operations.

To address this gap, we offer Blast Monitoring as a Service (BMaaS), a practical solution where companies can rent monitoring stations for one-time use without committing to a full investment.

The key advantage is that while clients can handle most of the process themselves, tasks like installation, maintenance, and instrumentation management requires a certain level of expertise.

Having a direct line to the manufacturer for support is a crucial part of our approach and one of our greatest strengths.

Why do I sometimes feel two pulses after a blast?

A blast generates two distinct types of energy that travel at different speeds. First, ground vibrations propagate through the earth at speeds ranging from 3 to 6 km/s, depending on soil and rock conditions. Second, air overpressure, the sound wave produced by the blast, travels through the air at the speed of sound which is approximately 340 m/s.

When you perceive two separate pulses, you're actually experiencing these two phenomena at different times. The first pulse is typically caused by ground vibrations transmitted through buildings and structures, which can resonate like a speaker membrane. The second pulse arrives later and is the air overpressure, the direct sound wave from the blast. This time difference explains the sensation of two distinct impacts.

Listen to an example of a blast event:

How does air overpressure differ from ground vibration in impact and timing?

Air overpressure and ground vibration differ both in how they travel and in how they are perceived. Ground vibration moves through the earth and may cause structures to shake, producing low-frequency sounds as buildings resonate. In contrast, air overpressure is the shockwave that travels through the air and is experienced primarily as sound.

Because they travel at different speeds, ground vibration being significantly faster than air overpressure, they reach observers at different times. Ground vibrations typically arrive first, followed by the air overpressure, creating the sensation of two distinct events from a single blast.

Listen to an example of a blast event:

What kinds of output (waveforms, PPV charts, compliance reports) do monitoring solutions provide?

In general, PPV, PVS, frequencies and waveforms are presented. Those values, either using Zero Crossing of FFT for frequency analysis, are summarized. Those results can also be used to optimize blasting operations sequence, and identify any anomalies that would have happened in the blasting sequence.

How can monitoring help reduce environmental and community impact concerns?

Beyond compliance, blasts are events that generate noise and vibrations. Monitoring may help reduce environmental and community impact concerns by providing precise and easily interpretable data on every blast event as well as simplicity of installation, operation, maintenance. Be at peace with our blast monitoring solution!

Manage environmental noise with our social acceptance practical guide.

How do automated alerts and remote dashboards improve operational control?

Automated alerts and remote dashboards enhance operational control by providing real-time information, allowing teams to quickly adjust parameters between blasts without needing to go on-site or rely on technical personnel. Data is centralized and easily shareable, which improves coordination and decision-making across teams. This streamlined access to critical information helps ensure compliance, reduces downtime, and supports more efficient blast planning.

What special considerations are needed for monitoring near historic or vibration-sensitive structures?

Monitoring near historic or vibration-sensitive structures requires special care, as these buildings and any equipment within them are often more vulnerable to damage due to their age, construction methods, or fragility. These concerns are addressed in several industry standards and guidelines.

Typically, lower vibration limits are applied to ensure the safety and integrity of such structures. It is especially important to detect and record even low-level vibrations, as what may be acceptable for modern buildings could pose a risk to more delicate or heritage structures.