Every breakthrough starts with a simple question: "What if we could do it better?"

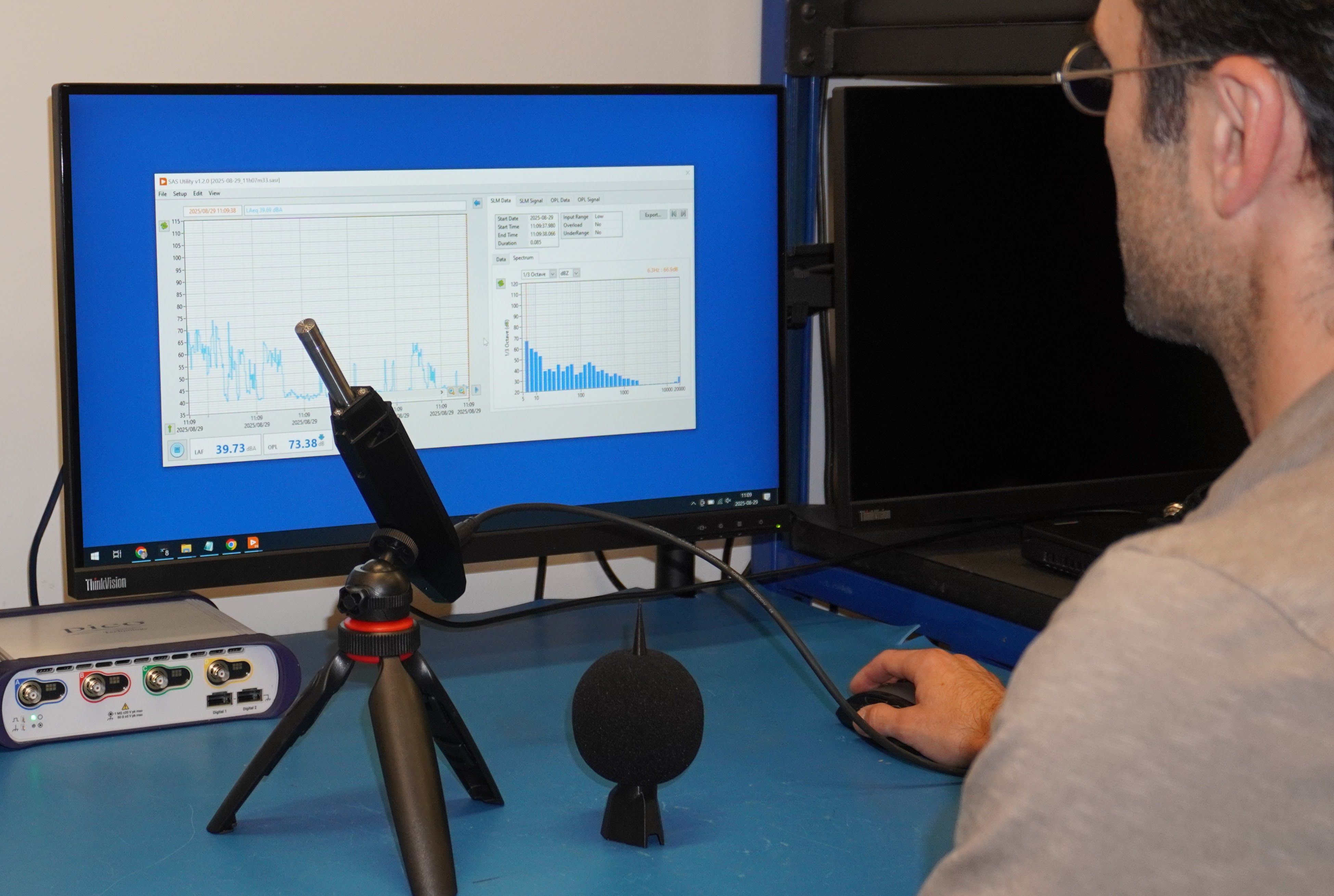

For Soft dB, that question led to the SAS – Smart Acoustic Sensor. In just one year, our R&D team turned an idea into a rugged, Class 1 sound level meter built to monitor noise, overpressure, and infrasound, all at once. A first of its kind.

Built for short-term measurements and long-term monitoring, and tested in the harshest conditions, the SAS embodies who we are: innovators and passionate acousticians obsessed with precision and real-world performance.

To understand how this sensor came to life, we sat down with some of the minds behind it. Here's their story in their own words.

Meet the Minds Behind the SAS

Alex Boudreau

After having completed a PhD in electrical engineering and digital signal processing in 2003, Alex Boudreau joined Soft dB and quickly became an associate. He was in charge of R&D from the beginning and his innovations allowed Soft dB to stand out offering innovative products. Since then, Soft dB grew and launched several divisions: Sound Masking, Instrumentation and Monitoring. Alex Boudreau, as a CTO, is a key element in the commercial success of these divisions and Soft dB as a whole.

Louis-Alexis Boudreault

Louis-Alexis Boudreault, electrical engineer, joined in 2010 as an intern like many others at Soft dB. Working as a noise and vibration consultant at first, he quickly showed interest in instrumentation design. He is for instance the main product designer for the I-Track system, a world-renowned sound-intensity imagery system. Over the years, he grew to be a noise and vibration measurement expert with in-depth knowledge on the sensors, signal processing, electronics and standards compliance. Louis-Alexis Boudreault became an associate in 2015 and is now the R&D deputy director.

Behind the SAS stands also Soft dB's entire R&D team: a group of world-class engineers, software specialists, and acousticians who have been innovating for nearly 30 years. Their deep expertise, carried from one Soft dB's products to the next, allowed the team to move fast, solve complex challenges, and deliver a sensor that's truly ahead of its time.

The Spark

What sparked the idea for the SAS? What gap did you see in the market that others had overlooked?

We used to have two dedicated microphones for sound level measurements (SLM) and blast overpressure applications and we believed that we could do these two applications using the same microphone and some clever signal processing tricks. And while we were at it, why not do infrasound either.

Also, we wanted to have a rugged outdoor sound sensor that would protect the microphone from the harsh elements while still being Class 1 compliant. Many solutions on the market offer a Class 1 sound level meter, but it's not necessarily compliant when you add everything needed to perform 24/7 outdoor noise monitoring such as extensions, environmental protection, solar power, etc.

Last but not least, we wanted a self-contained sensor that would only output computed measurements in a digital format. This allows three main benefits: the first one is to lower the electrical noise because the analog signal path is kept to a minimum. The second one is to relieve the monitoring station central controller from processing the raw signal. And the third one is to certify the instrument as it is without external components to make it work.

Introducing the SAS

If you had to describe the SAS in just two sentences, what would you say? Which problems does it solve for people in the field?

We can describe the SAS with a few words: an "All-in-One" sensor.

This statement underlines two aspects: the first aspect is that everything is needed in one package. You don't need an additional environmental protection, or microphone extension cable. The second aspect is that you can do SLM, blast overpressure and infrasound at the same time using the same instrument.

The Bold Choice

Most sound level meters have an integrated screen with a separate microphone. Why did you choose the opposite approach? How does that decision make the SAS more robust and better suited for long-term, multi-contaminant monitoring?

The most "controversial" design choice for the SAS was to incorporate the microphone connection inside the body of the instrument. This is a clash with the classical approach of a sound level meter inside a cabinet with a distant microphone connected using an extension.

We wanted to fully control how the instrument would be used and prevent the user from using a microphone extension cable. We also wanted to protect this sensitive connection from the harsh elements. Lastly, we wanted to "pair" the microphone with the electronics in order to fully certify the instrument: we didn't want the user to switch the microphone for whatever reason.

In the end, removing a feature allowed us to design a better instrument.

What Makes It Unique

What makes the SAS truly stand out from everything else on the market? Is there a particular innovation or feature you're most proud of?

The sheer number of features is what makes the SAS stand out from everything else on the market. While you may find another product having one or more features that the SAS offers, you won't find another instrument with as many features packed in.

As mentioned earlier, computing SLM, blast overpressure and infrasound metrics at the same time is something that no other instrument does on the market, and this is why we have a patent pending on this application.

The SAS also embeds a seamless dynamic range switching that offers 117 dB of dynamic range. While we keep the classic low/high range approach for certification purposes, you can view the automatic range as a continuous dynamic range spanning the low and high ranges at once. In fact, the auto range also passes all certification tests, but the standard is not written with this feature in mind as it's too advanced.

The SAS also packs a lot of compensation algorithms to provide the most precise measurements. For instance, the SAS compensates for the frequency response of the microphone, for the environmental protection, and for the temperature effect on the microphone.

The SAS computes an impressive quantity of metrics. While it computes every classical SLM metrics, it also computes the dBG weighting which is useful for infrasound applications. For spectral analysis, it computes 1/3 octave bands from 6.3 Hz to 20 kHz and 512 lines FFT spectrum with overlap. This spectral analysis feature set is only available on the most high-end and expensive sound level meters. The SAS also offers an on-board time signal compression ranging from 24 bit/48 kHz to 4 bit/12 kHz. Last but not least, the SAS offers a calibrated pressure time signal in pascals for blast events where measurement of blast overpressure is regulatory.

The field calibration aspect of noise monitoring is an ordeal. Every now and then, someone must go to the field to check the calibration of the microphone. The good practice book would like to have this done as frequently as possible, but sending someone in the field to do that is a significant expense in a noise monitoring program. Therefore, we implemented a feature, which injects a signal directly at the back of the microphone diaphragm to check for sensitivity deviations and broader issues such as water damages, etc. This sensor-check can be performed by the instrument itself at a periodic interval such as every day at midnight for instance. While it doesn't replace a standard field calibration, it can certainly make them less frequent and also provides a quicker response time if something goes wrong with the instrument.

What we are mostly proud of is not something that stands out on a spec sheet but which is very important in the real world of 24/7 noise monitoring: power consumption. The SAS only consumes less than 0.5W which is a feat in itself knowing the quality of analogue signal processing, the extensive digital signal processing and RS485 digital communication driver. Every aspect of the electronic design was taken into consideration to lower power consumption while making no compromise on the overall feature set.

The Journey to Get There

Developing the SAS took about a year. How did that journey unfold behind the scenes? What role did collaboration between R&D and field experts play in shaping the product?

Our first integrated smart sensors were the SVS – Smart Vibration Sensor. Our field team quickly saw the potential of this "all-in-one" approach for sensors as it simplified field deployments, it streamlined the annual certification process, thus reducing cost of ownership, and it improved the overall reliability of the product since it didn't have separate parts and the signal processing is not separated from the sensor.

So basically, the list of requirements came directly from the field team. They wanted the same benefits they got from the SVS for SLM application which was experiencing the same problem but to an even higher degree. Field deployments with environmental protections, microphone extension cables, etc. were complicated. Returning the kit annually for periodic certification was an ordeal since you needed to return everything, not only the microphone, but also the extension and sound level meter in order to remain compliant with Class 1. Not to mention that microphones were often swapped by non-technical end users that didn't realize this would affect the certification. Lastly, the field team was exhausted from the noise issues caused by defective connections to analogue electrical signals and also from water damage to the microphones and sensitive preamp electronics.

The field team is a key element in our design process as they are at the two ends of that design process: they first define the technical requirements of the product and they are also our field testers. They sometimes joke with us at R&D telling us to leave our lab and go out in the field more often, and they are right!

Patents and Innovation

The SAS is built on a unique patent. How would you explain this innovation in simple terms, and why does it matter?

Having simultaneous sound level and blast-overpressure measurements is not a widespread application, but it's important for open-pit mines and quarries, and sometimes large construction sites. These activities generate noise, vibration and air-overpressure caused by the rock blasting. Historically, the sound and vibration measurements were split in two different markets: sound level meters on one hand and seismographs on the other. The air-overpressure measurements were handled by seismographs as an additional sensor to the vibration measurements and the sound level meters industry didn't care about it. Since we do both noise and vibration monitoring, we found it silly to use two separate microphones to measure basically the same physical signal.

Combining the SLM and blast overpressure in a single instrument was a clever idea and no one was doing it on the market. For this, we needed to process the microphone signal from the typical 10 Hz-20 kHz for sound level measurements to 2 Hz-250 Hz for blast overpressure. While the signal processing techniques that we implemented are not complicated for a signal processing expert, we believed the benefits provided by the technique were important enough to claim. A patent is not only useful to protect our technical innovations but also to promote them. This application also helped to reduce the cost of ownership of the SAS, since only one sensor is needed in inventory to comply with both applications.

Smart Sensors, Smarter Vision

What's Soft dB's broader vision for smart sensors and multi-contaminant monitoring? How does the SAS fit into that philosophy?

The smart sensor approach offers several benefits:

The first benefit is distributed processing. If a central processing unit was required for multiple analogue sensors, it would need to be designed for the worst-case scenario of a lot of sensors at once. Therefore, this central processing unit would be overdesigned for most applications where one or two sensors are required. Having smart sensors with on-board processing relieves the central processing unit from this task and it only becomes a data management controller. Increasing the number of smart sensors on this data management controller marginally increases the required power. That being said, there is a limit to which a smart sensor should be stand-alone: for instance, it's not desirable to have 4G communication, or a solar charge controller, in each smart sensor. There is a balance point to tell which features should be handled by the smart sensor and which features are better kept in the central controller.

The second benefit is periodic certification. Since the sensor is integrated, it's certified as it is without having to include the central controller in the certification. Moreover, when sending the smart sensor back to the lab for annual certification, you can easily swap it with another one while the previous sensor is being serviced. Since the certification follows the smart sensor, it's only a matter of disconnecting the old sensor and connecting the new sensor for the measurement to continue. The central controller will take care of starting the measurement when the new smart sensor is detected.

The third benefit is future proofing. The only requirement for our smart sensor is to be compatible with the smart sensor port of the central controller. Therefore, we can design a new smart sensor for other physical measurements and we know it will work as long as it uses the same digital communication. If we foresee a need for a specific sensor in the market, we can easily create a smart sensor and integrate it to our monitoring solution.

Defining Moments

What was the most defining moment, or biggest challenge, in developing the SAS? Looking back, what makes you most proud of this product?

It's hard to pick a single defining moment or a biggest challenge in the SAS development as every aspect was critical.

The electrical design was a challenge in achieving the lowest noise level, a large dynamic range, low-power consumption and low price, especially in such a small form factor.

The mechanical design was also a challenge. Providing an acoustically transparent enclosure while also providing good environmental protection was a very hard task. Any kind of rain hat on the microphone has an important effect on acoustical performance and Class 1 conformity is very hard to meet in these situations as the tolerances are defined for a classic hand-held sound level meter with a simple foam windscreen, not for an environmental protection shroud.

Last but not least, the digital signal processing was very substantial and we doubted that the chosen microcontroller would be powerful enough for the task. In the end, we managed to implement everything and even more!

The Road Ahead

Where do you see the future of environmental noise and vibration monitoring heading? And what role will products like the SAS play in shaping it?

The future of environmental noise and vibration monitoring is definitely with smart sensors. Other successful actors in the market are also talking about this approach.

Noise and vibration monitoring is an expanding market as the regulatory environment integrates more noise and vibration regulations and as populations are more aware of noise and vibration in the environment.

The key is to offer a noise and vibration monitoring solution that is easy to implement, easy to use and scalable. The smart sensor approach definitely plays a role in this.

The SAS is a milestone for Soft dB's monitoring solutions as it provides huge benefits in the reliability, precision and simplicity of noise monitoring. Our field team knows a lot about that.

The SAS is also a milestone in the market as it sets Soft dB as a leader in this field. Designing a smart weather sensor is simple enough. Designing a smart vibration sensor is much harder. Designing a smart acoustical sensor with as many features is in a class of its own and is the result of years of combined expertise.

Conclusion

The SAS isn't just a sensor, it's a statement.

Proof that precision, reliability, and innovation can live in the same compact package. For our team, it represents more than a product launch; it is the result of years of acoustics and vibration expertise distilled into one idea: building smarter tools for realities of the field.

And this is only the beginning.

About Soft dB's R&D Team

For nearly 30 years, Soft dB's in-house, world-class R&D team has been redefining the future of acoustics and vibration innovation.

Holding nine patents, they've pioneered technologies ranging from sound masking systems and environmental monitoring stations to active noise control solutions and even controllers for advanced electronic microscopes. Their expertise spans the entire spectrum of high-tech acoustics and vibration.

This deep knowledge, carried from one product to the next, allows the team to accelerate development and ensure every new creation is truly cutting-edge, and built for the realities of the field.

When new needs arise, Soft dB's R&D drives every stage of product development, from concept to field-ready innovation, working hand in hand with field experts to ensure the final product truly meets real-world needs.

It's this unique blend of expertise and collaboration that turns bold ideas into industry-defining solutions.