CASE STUDY - WORKSTATION PROTECTION

Matra succeeds in limiting noise exposure with Soft dB Acoustic enclosures!

In order to comply with noise exposure regulations and to improve the safety of its employees, Matra needed to take action to reduce the noise exposure within their factory.

Contact our industrial noise control expertsWith workstations being impacted by too many noise sources, Soft dB was tasked with developing an effective tailor-made solution to reduce the noise levels - all while staying within budget.

After careful inspection and various simulations, our team proposed the installation of a Soft dB patented acoustic enclosure, with the versatility to be tailored precisely to Matras specifications.

The results of the study produced an astounding 60% reduction in acoustic energy!

Objective: Reduce the Overall Noise Exposure to Workers

The customer wanted to reduce the excessive noise exposure for their employees.

Given the large number of contributing sound sources in the targeted workstation area, our team conducted assessments and carried out simulations to find the most effective solution for their unique situation.

Approach: steps to address the objective

Process and stages:

- Developing a detailed analysis involving the measurement of sound pressure and intensity, covering all noisy equipment in the area of concern.

- Sound modeling of the area using RAP-ONE II software, developed by Soft dB

- Evaluation, quantification and optimization of acoustic treatment recommendations

Soft dB's simulations predicted a 5-10 dBA reduction in noise exposure (shift dosimetry), thus meeting the objective of reducing the overall noise exposure.

Solution: Installation of an Acoustic Enclosure

As per the results and meeting the clients’ requirements, Soft dB’s Soundproofing Division designed a custom-made acoustic enclosure and our team proceeded with the installation.

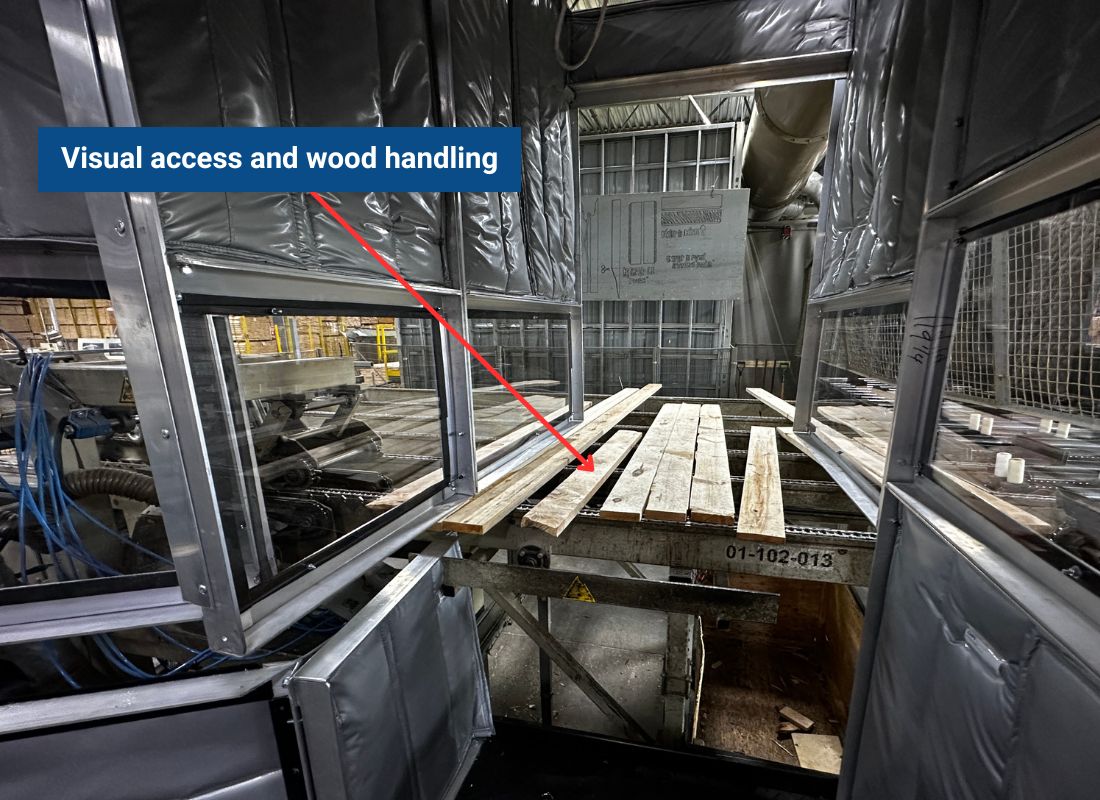

Designing the custom enclosure required several considerations to achieve optimal results - visual access, handling of wood planks, openings for sorting wood, and a ventilation opening of a silencer to ensure adequate airflow for safety of the employee.

Objective Met - Noise Reduction of 6 dBA (60%).

Soft dB used the process of dosimetry to conduct an assessment of an employee’s noise exposure throughout the duration of their shift. Results from this study confirmed the achievement of the objective, with sound level reductions of 5 to 8 dBA, depending on position in the workstation zone.

Despite the necessary requirement to have openings in the acoustic enclosure - for proper operation of equipment - the attenuation achieved was also reported as being significantly noticeable to the employee.

Customer

Matra Group is an undisputed leader in the processing of Eastern Canadian White Pine, averaging over 30 million board feet (FBM) per year. Their company uniquely specializes in the manufacturing and distribution of window and door components, in addition to primed moulding.

A Strategic Partner with IPI - A Leader in Industrial Insulation

Soft dB has developed a partnership with IPI Isolation Thermique in the design of our acoustic blankets. Partnering and collaborating with a leader in industrial insulation enables us to deliver a high-quality product, worthy of this multidisciplinary association.

The Solution to your Industrial Noise Challenges

Do you work in an environment with noisy mechanical equipment? Our acoustic blankets and panels will help you to effectively reduce the exposure of industrial noise. If preceded by a noise reduction study by our experts, the results of our solution are 100% guaranteed.

Tell us about your project