Is Industrial Soundproofing Essential for a Pulp and Paper Mill?

In the complex realm of pulp and paper production, effectively managing industrial noise has emerged as a multifaceted challenge. With this perspective in mind, this page is committed to providing a thorough and enlightening exploration of the crucial importance of industrial soundproofing.

Contact Our Industrial Soundproofing ExpertsWe will shed light not only on the specific challenges inherent in this demanding sector but also on the key machines that play an essential role in the production process, with a particular focus on their respective noise levels.

Furthermore, we will closely examine the strategic advantages that industrial soundproofing offers to plant managers, highlighting how this practice can not only preserve the health of workers but also contribute significantly to optimizing operations and enhancing the overall performance of the factory.

Challenges of Industrial Noise in Pulp and Paper Mills

Industrial noise goes far beyond being a mere nuisance within pulp and paper mills. Its impact extends well beyond, posing significant health risks to workers while leaving a noticeable imprint on crucial aspects such as productivity, the quality of the final product, and overall employee satisfaction.

A thorough understanding of these challenges is therefore imperative for proactive and informed management of industrial noise issues within these industrial environments.

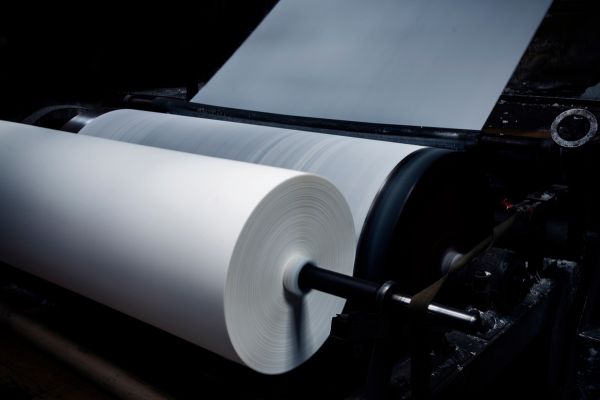

The operation of a pulp and paper mill is a complex process orchestrated by a series of specialized machines and equipment.

From the initial shredding of wood to the paper-forming stage, each step contributes to the creation of the final product. Wood chippers reduce the raw material into fibers, which are then processed in hammer mills to achieve the optimal consistency. The process continues with the use of paper presses, where the fibers are compressed to form paper sheets.

Every stage of this production involves robust and powerful machinery that can potentially generate high levels of noise. The sources of industrial noise in a pulp and paper mill mainly come from wood processing machines, transport systems, paper presses, and other equipment associated with material handling.

The diversity of these activities creates a complex sound environment, requiring special attention to industrial soundproofing to preserve the health of workers and optimize operations.

1. Wood Chippers

Wood chippers, essential in manufacturing, generate significant noise levels. Soundproofing these machines is crucial to ensure the safety of workers and minimize auditory risks.

Noise Type: The noise produced by wood chippers is often impulsive and variable in nature. Shredding phases can generate sudden sound peaks, contributing to an impulsive character, while variations in workload can create fluctuations in sound level, characteristic of variable noise.

Sound Levels: Between 90 dB and 110 dB.

2. Hammer Mills

Responsible for reducing wood fibers, hammer mills produce high noise levels. The integration of advanced soundproofing technologies is imperative to ensure a healthy and productive work environment.

Noise Type: Hammer mills generate predominantly continuous and variable noise. The constant rotation of the hammers produces a continuous sound, but variations in workload can lead to changes in noise intensity, contributing to its variable nature.

Sound Levels: Between 85 dB and 105 dB.

3. Paper Presses

While crucial to the process, paper presses can emit constant noise. The adoption of modern industrial soundproofing technologies is essential to create a sustainable environment while maintaining optimal production quality.

Noise Type: The noise from paper presses tends to be continuous. These machines typically operate steadily during the paper compression and forming processes, generating constant noise.

Sound Levels: Between 80 dB and 100 dB.

Benefits of Industrial Soundproofing for the Pulp and Paper Mill

Preservation of Workers' Health

Soundproofing reduces the risks of hearing loss, stress, and other health issues associated with industrial noise, thereby preserving the well-being of workers.

Improved Productivity

By lowering noise levels, soundproofing contributes to increased worker concentration, reducing production errors and enhancing overall efficiency.

Compliance with Local Regulations

Soundproofing helps pulp and paper mills comply with environmental standards by reducing sound emissions, thereby avoiding potential fines.

Quality of the Final Product

A quiet working environment promotes better attention to detail, ensuring consistent quality of the final product.

Why is Industrial Soundproofing Crucial for Pulp and Paper Mills?

The significance of industrial soundproofing within pulp and paper mills is justified by the variety of noises emitted throughout the production process.

Machines like wood chippers and hammer mills generate continuous noise during the transformation of wood into fibers. This constant noise can lead to auditory fatigue and disturbances in the work environment.

Paper presses, on the other hand, produce variable noise depending on the compression phase, creating sound fluctuations in the mill.

Furthermore, certain operations may generate intermittent noises, characterized by periods of sound activity interspersed with moments of relative silence. Lastly, sources of impulsive noise may also be present, especially during rapid changes in the production process.

Targeted soundproofing of these different sources of industrial noise aims to create a controlled acoustic environment, preserving the auditory health of workers and optimizing the overall operation of the mill.

Frequently Asked Questions by Pulp and Paper Mill Managers

Q1: How can industrial noise affect the health of workers in a pulp and paper mill?

Industrial noise can lead to issues such as hearing loss, stress, and sleep disorders. Soundproofing aims to prevent these negative impacts.

Q2: Which machines are the most critical in terms of noise levels?

Wood chippers, hammer mills, and paper presses are among the loudest machines. Soundproofing them is, therefore, a top priority.

Q3: How can soundproofing improve the productivity of the mill?

By reducing noise levels, soundproofing promotes better concentration, reduces production errors, and enhances overall operational efficiency.

Q4: How to choose the best soundproofing solutions for specific machines?

An assessment by acoustic experts of noise levels, combined with an understanding of the characteristics of each machine, guides the selection of the most effective industrial soundproofing solutions.

Q5: What are the financial benefits of investing in soundproofing for a pulp and paper mill?

Financial benefits include reduced costs related to production errors, improved compliance with environmental standards, and prevention of medical costs associated with health issues of workers exposed to noise.

Industrial Soundproofing in the Pulp and Paper Sector: A Necessary Solution?

In conclusion, managing industrial noise in pulp and paper mills represents a multifaceted challenge that cannot be underestimated. This in-depth exploration of the crucial importance of industrial soundproofing has highlighted the specific challenges of this complex sector. Key machines, such as wood chippers, hammer mills, and paper presses, have been identified as significant sources of high noise levels.

It is imperative to emphasize that industrial soundproofing should not be viewed as a mere option but rather as an essential requirement for these demanding production environments. Engaging professionals in industrial acoustics becomes a strategic step to minimize risks associated with industrial noise, ensure compliance with regulations, and optimize overall plant performance.

These experts will not only guide the selection of the most suitable soundproofing solutions but also contribute to creating a work environment that balances worker health, operational efficiency, and excellence in production.

Mastering Industrial Noise in Your Pulp and Paper Mill

Put an end to industrial noise in your pulp and paper mill with our expertise in industrial soundproofing. Our team of acoustic experts is ready to design customized solutions tailored to your specific production environment.

Contact Our Industrial Soundproofing Experts