Industrial Noise: What Is It and How to Control It?

Industrial noise - also known as industrial noise pollution - refers to unwanted or excessive sound produced by industrial activities and processes. This is a type of noise that comes from, among other things, the use of equipment such as pumps, motors, fans, conveyors, presses and any other industrial process.

Contact Our Experts to Reduce Industrial NoiseIndustrial noise is primarily a negative effect of industrial equipment and processes.

In industrial environments, noise levels often exceed 80 dBA, which is considered the threshold for potential hearing damage after prolonged exposure, according to Health Canada and the World Health Organization (WHO). These noise levels can lead to irreversible hearing loss and other health issues as well as decreased productivity for workers exposed to them without adequate protection.

In this light, industrial noise control solutions are becoming indispensable for all industries.

What Are the Types of Industrial Noise?

The different types of industrial noise encompass the various ways in which noise is generated and propagated in industrial settings. The four main types of industrial noise are continuous, impulsive, intermittent, and tonal.

Continuous noise: This type of noise is characterized by a stable sound emission and originates from machines or processes operating continuously, such as engines and conveyor belts.

Continuous noise of a crusher

Intermittent noise: This type of noise is characterized by periods of sound activity alternating with periods of inactivity. It is produced by sporadic activities such as the stopping and starting of certain equipment.

Sporadic noise from a tracked excavators

Impulsive noise: Also known as impact noise, this type of noise leads to a short but significant increase in sound levels and is generated by sudden events such as falling metal parts or the use of a mechanical press or hydraulic hammer.

Impact sound from a hydraulic hammer

Tonal noise: In this type of noise, the majority of the acoustic energy is centered around specific frequencies, such as for certain fans, which gives a specific tone to the sound emission.

Tonal noise from a mining fan

Analysis and characterization of these types of noise are essential to identify dominant sources, predict how noise propagates in the environment under study, and implement effective noise control measures.

What Are the Characteristics of Industrial Noise?

Industrial noise, like any other form of noise, can be described by several key metrics. The primary characteristics include:

- Intensity or Sound Level (dBA): Industrial environments can produce high levels of noise due to the operation of machinery, engines, and heavy equipment. The intensity of industrial noise usually ranges from 70 to 120 dBA, depending on the source.

- Frequency (Hz): The frequency range of industrial noise can vary, but it often includes low-, mid-, and high-frequency components, depending on the source. Low-frequency noise is generally more difficult to control than high-frequency noise, and noise control solutions are developed accordingly.

- Duration: Industrial noise can be either continuous, intermittent or impulsive, depending on the specific processes and activities underway. Continuous noise can last for several minutes or even hours, while intermittent noise may occur for only seconds or minutes at a time. Impulsive noise, on the other hand, typically lasts less than a few seconds.

Understanding these characteristics and identifying which ones contribute most to problematic noise emissions are essential for developing effective noise mitigation strategies.

What Are Sources of Industrial Noise Pollution and their Sound Levels?

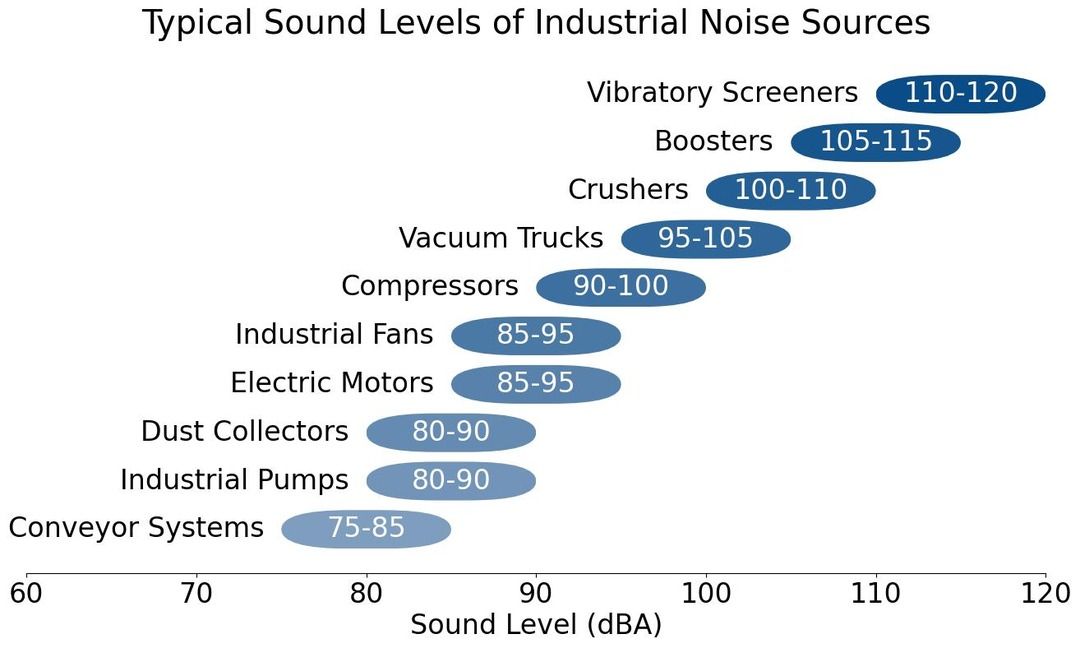

In the field of industrial noise, sound levels can vary considerably, depending on the sources, processes, and equipment involved. Here are some common industrial noise levels from various sources.

Sound levels of different industrial noise sources. Conveyor systems: 75 to 85 dBA. Industrial pumps: 80 to 90 dBA. Dust collectors: 80 to 90 dBA. Electric motors: 85 to 95 dBA. Industrial fans: 85 to 95 dBA. Compressors: 90 to 100 dBA. Vacuum trucks: 95 to 105 dBA. Crushers: 100 to 110 dBA. Boosters: 105 to 115 dBA. Vibratory Screeners: 110 to 120 dBA.

What Are Adverse Effects of Industrial Noise Pollution?

The negative effects of industrial noise pollution are substantial and impact various aspects of human life. According to Health Canada, exposure to noise levels exceeding 80 dBA for extended periods can potentially lead to hearing disorders, stress-related issues, and decreased productivity.

Chronic exposure to industrial noise can lead to permanent hearing loss and other long-term health problems. According to the World Report on Hearing from the WHO, more than 16 % of adults worldwide suffer from hearing loss due to workplace noise exposure.

How to Prevent Industrial Noise and Protect Workers?

In consideration of the well-being of workers, various government regulations, such as the Regulation Respecting Occupational Health and Safety (RROHS) in Quebec and the Occupational Health and Safety Act (OHSA) in Ontario, limit industrial noise. Regulations may include setting permissible noise levels, requiring the use of industrial noise control technologies and conducting regular noise studies.

The implementation of preventive measures begins with a thorough noise impact study. This assessment involves measuring noise levels in different areas of the industrial facility. The data collected helps identify the primary sources and noise levels, allowing employers to implement appropriate industrial noise control strategies.

Technical noise control solutions aim to reduce industrial noise at the source, along the transmission path between equipment and workers, or at the receiver (the worker).

In addition to using quieter equipment, the introduction of noise reduction technologies, such as acoustic blankets and custom-made removable acoustic barriers, allows for effective control of industrial noise at the source.

Administrative measures complement technical controls and aim to reduce workers' exposure to high noise levels. This may involve establishing work schedules that limit exposure time to noisy areas, creating quiet rest zones, and implementing a hearing conservation program. Proper training and education on the risks of noise exposure are crucial for preserving workers' hearing health.

Control Industrial Noise Effectively: Mitigate at the Source

Treating industrial noise sources at the source is both the most effective means and the one preferred by the RROHS in Quebec and the OHSA in Ontario to control noise pollution.

Manufacturers are increasingly incorporating noise reduction technologies into the design of their equipment and machines.

Optimizing industrial processes can lead to quieter operations and overall improved efficiency. By investing in quieter technologies, regularly upgrading their equipment, and mitigating the noise from their machines with acoustic enclosures, industries can proactively address noise pollution issues.

Learn on how our experts reduced industrial noise using acoustic enclosures by reading our case studies on protecting a workstation and reducing noise at the source.

Mastering Industrial Noise from Your Equipment and Machines: A Solution of Noise Pollution

Do you want to see for yourself a solution that will help you control industrial noise?

Don't miss this short video!

Here Are Some Frequently Asked Questions About Industrial Noise

How to Establish an Action Plan for Industrial Noise Treatment?

To establish an effective action plan for industrial noise treatment, a comprehensive noise assessment of the work environment must first be conducted to identify noise sources and intensity levels. Based on the findings, appropriate noise control measures can be planned and implemented. In accordance with governmental regulations and guidelines on sound emission, engineering controls to reduce noise at the source are the preferred mitigation strategy. These measures include noise control technologies such as acoustic blankets and acoustic barriers.

What Are Industrial Noise Control Measures?

There are a variety of industrial noise control measures. Soft dB offers unique noise control technologies such as acoustic blankets and acoustic barriers, which are all designed for source mitigation, complying with governmental industrial noise regulations and guidelines for the well-being of workers such as the RROHS in Quebec and the OHSA in Ontario.

By How Many Decibels Can Industrial Noise Be Reduced With Noise Control Measures?

With appropriate noise control measures, industrial noise can be reduced by up to 30 dBA with treatment at the source. However, since each project is different and requires individual attention, a prior assessment of the potential reduction in noise levels through a noise study is required.

Why Is Source Mitigation the Preferred Noise Control Solution Over Individual Hearing Protection for Workers?

Noise mitigation at the source is the preferred noise control method over personal hearing protection, as it promotes better compliance with government regulations and guidelines. It should be noted that personal protective measures are to be used as a last resort, according to the RROHS and the OHSA. The effectiveness of these measures results solely from their use and their implementation may be overestimated.

What Type of Noise Poses the Highest Risk of Hearing Loss?

Impulse noise, often associated with sudden events producing abrupt and loud sounds, is generally the most at risk of causing hearing loss. According to the WHO’s World Report on Hearing, due to its intense and brief nature, this type of noise can significantly damage the hair cells in the inner ear, thereby increasing the risk of permanent hearing loss. It is, therefore, essential to take preventive measures, such as source industrial noise control in environments where this type of noise is prevalent.

Industrial Noise Must Be Controlled

Industrial noise pollution poses a significant challenge to worker health. However, it is possible to mitigate the adverse effects of industrial noise by implementing effective noise control measures and adequately protecting workers. By prioritizing noise reduction at the source and employing technical and administrative controls, industries can create safer and healthier working environments while contributing to a quieter and more sustainable world.

Contact Our Experts to Reduce Industrial Noise